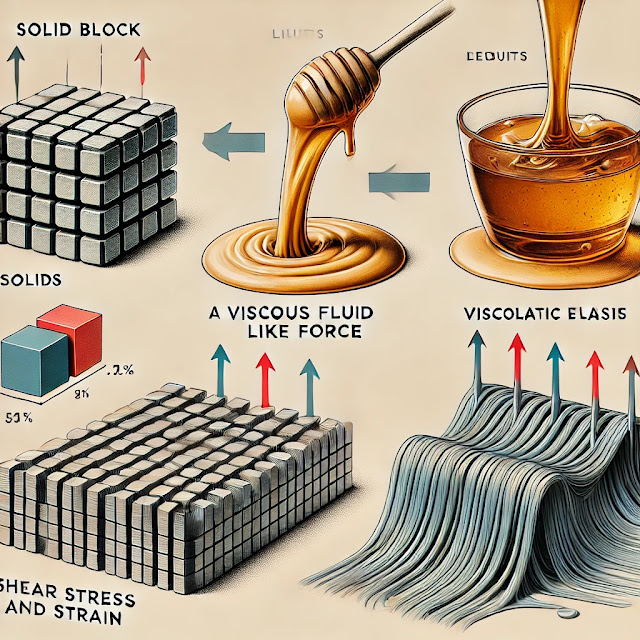

Definition: Rheology is the study of the flow and deformation of matter, particularly liquids and soft solids. It encompasses the understanding of how materials respond to applied forces, focusing on their viscosity, elasticity, and plasticity.

Key Rheological Properties:

Viscosity: A measure of a fluid's resistance to flow. Higher viscosity means the fluid flows more slowly.

Elasticity: The ability of a material to return to its original shape after deformation.

Plasticity: The extent to which a material can undergo permanent deformation without breaking.

Rheology in Pharmacy

Importance: Rheology is crucial in the pharmaceutical field for several reasons:

Formulation Development:

Consistency and Stability: Rheological properties influence the consistency and stability of pharmaceutical formulations such as creams, gels, ointments, and suspensions. Proper rheological control ensures that these products remain stable during storage and use.

Homogeneity: Ensures that active pharmaceutical ingredients (APIs) and excipients are uniformly distributed, which is vital for the efficacy and safety of the medication.

Manufacturing Processes:

Mixing and Blending: Rheology helps in optimizing the mixing and blending processes, ensuring that ingredients are adequately combined without degrading.

Filling and Packaging: Understanding the flow properties of formulations aids in the efficient filling and packaging of products, reducing waste and ensuring consistency.

Drug Delivery:

Bioavailability: Rheological properties can affect the bioavailability of drugs. For example, the viscosity of a solution can influence the rate at which a drug is released and absorbed in the body.

Topical Applications: For topical formulations like creams and ointments, rheology determines how easily the product can be applied and spread on the skin.

Patient Compliance:

Ease of Use: Rheological properties influence the ease of administration and patient experience. For example, the ease with which a liquid medication can be poured or cream can be spread affects patient compliance.

Quality Control:

Consistency: Rheological measurements are used in quality control to ensure batch-to-batch consistency of pharmaceutical products.

Performance Testing: Helps in predicting the performance and behavior of formulations under different conditions, ensuring that they meet the required standards.

Applications in Pharmacy

Suspensions and Emulsions:

Ensuring uniformity and stability to prevent settling or separation of components.

Creams and Ointments:

Optimizing spreadability and texture for better patient acceptance and therapeutic efficacy.

Gels:

Controlling the gelation process and ensuring the appropriate viscosity for application and drug release.

Tablets and Capsules:

Improving the flow properties of powders during the manufacturing process to ensure uniformity and quality of the final product.

Controlled Release Formulations:

Designing formulations that release the drug at a controlled rate, enhances therapeutic outcomes.

Summary

Rheology, the study of the flow and deformation of materials, is essential in pharmacy for developing stable, effective, and user-friendly pharmaceutical products. By understanding and controlling rheological properties, pharmacists and pharmaceutical scientists can ensure the quality, efficacy, and safety of medications, ultimately improving patient outcomes and compliance.

0 Comments

Thanks for your feedback, ll get back to you soon