Microorganisms Used:

- Lactic Acid Bacteria (LAB): The most common microorganisms used for the fermentative production of lactic acid are lactic acid bacteria like Lactobacillus, Streptococcus, and Pediococcus. Yeast and fungi can also be used in some processes.

- Different strains are selected based on whether L-lactic acid or D-lactic acid is desired, as some strains produce only one enantiomer, while others can produce both.

Raw Materials:

- Carbohydrate Sources: Lactic acid is primarily produced from sugar-based substrates such as glucose, lactose, sucrose, or starch. Common sources include corn starch, sugarcane, whey, and other inexpensive carbohydrate sources.

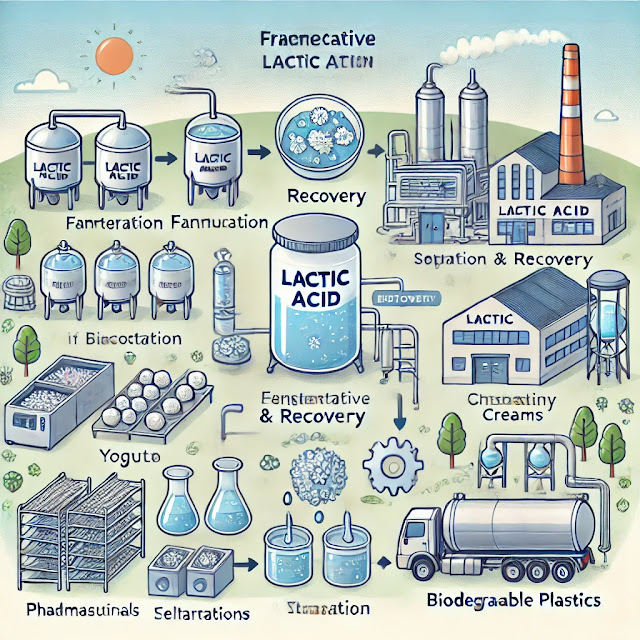

Fermentation Process:

- Anaerobic Conditions: Lactic acid fermentation occurs under anaerobic conditions where LAB metabolizes sugars and convert them into lactic acid.

- pH Control: The production of lactic acid leads to a drop in pH, which can inhibit the growth of LAB. To prevent this, pH is controlled by adding neutralizing agents like calcium carbonate (CaCO₃) or sodium hydroxide (NaOH) to maintain an optimal range.

- Temperature: The fermentation is usually carried out at 30°C–40°C, depending on the strain of bacteria.

- Fermentation Time: Typically, the fermentation process lasts 24–72 hours.

Recovery of Lactic Acid:

The recovery of lactic acid involves several steps to separate it from the fermentation broth, remove impurities, and concentrate it.

Cell Removal:

- Filtration or Centrifugation: After fermentation, the bacterial cells are removed from the broth by filtration or centrifugation.

Precipitation:

- Calcium Lactate Precipitation: If calcium carbonate is used to neutralize the pH during fermentation, lactic acid exists as calcium lactate in the broth. The lactic acid is separated by treating the solution with sulfuric acid (H₂SO₄), which precipitates calcium as calcium sulfate (gypsum), and lactic acid remains in the solution.

Purification:

- Crystallization: Lactic acid can be crystallized from the fermentation broth or recovered by evaporating the water under reduced pressure.

- Ion Exchange: Ion exchange chromatography can be used to further purify lactic acid by removing ionic impurities.

- Distillation: In some processes, vacuum distillation is used to concentrate and purify lactic acid.

Concentration:

- Evaporation: Lactic acid is concentrated by evaporating water to achieve the desired concentration, typically 80-90% for industrial purposes.

Uses of Lactic Acid:

Lactic acid has a wide range of applications across various industries due to its properties as an acidulant, preservative, and chemical feedstock.

Food Industry:

- Preservative: Lactic acid is used in processed foods and beverages as a preservative and pH regulator.

- Fermentation and Flavoring: It is also involved in fermentation processes for products like yogurt, cheese, pickles, and sauerkraut.

- Acidulant: Lactic acid adds a mild sour taste to foods and is used in confectionery, bakery products, and salad dressings.

Pharmaceuticals:

- pH Adjustment: It is used in the formulation of medicines to adjust pH levels.

- Lactate Ringer's Solution: Lactic acid is an essential component of intravenous solutions, such as Ringer's lactate, used to treat dehydration and electrolyte imbalance.

Cosmetics:

- Exfoliant and Moisturizer: Lactic acid is used in skincare products for its exfoliating and moisturizing properties.

- pH Balancer: It helps in balancing the pH of cosmetic formulations and has mild antibacterial effects.

Industrial Uses:

- Biodegradable Plastics (PLA): Lactic acid is polymerized to produce polylactic acid (PLA), a biodegradable plastic used in packaging, medical devices, and textiles.

- Solvents and Plasticizers: Lactic acid derivatives are used as eco-friendly solvents and plasticizers in various industries.

Textiles and Leather:

- Lactic acid is used in the textile and leather industries for dyeing and tanning processes, offering an eco-friendly alternative to synthetic chemicals.

Agriculture:

- Animal Feed: Lactic acid is used as an additive in animal feed to promote better digestion and preserve silage.

In summary, lactic acid's fermentative production is a relatively efficient and eco-friendly process that offers a diverse range of applications across food, pharmaceuticals, cosmetics, plastics, and more.

0 Comments

Thanks for your feedback, ll get back to you soon